| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : Huashida

Model Number : HSD 6-160

Certification : CE,ISO:9001

Place of Origin : Qingdao,China

MOQ : 1 set

Price : 50000-600000 USD

Payment Terms : L/C,D/A,D/P,T/T

Delivery Time : 50-90 days

Packaging Details : standard package

Model NO. : 6-160 mm

Condition : NEW

Material : PVC/NBR/EPDM

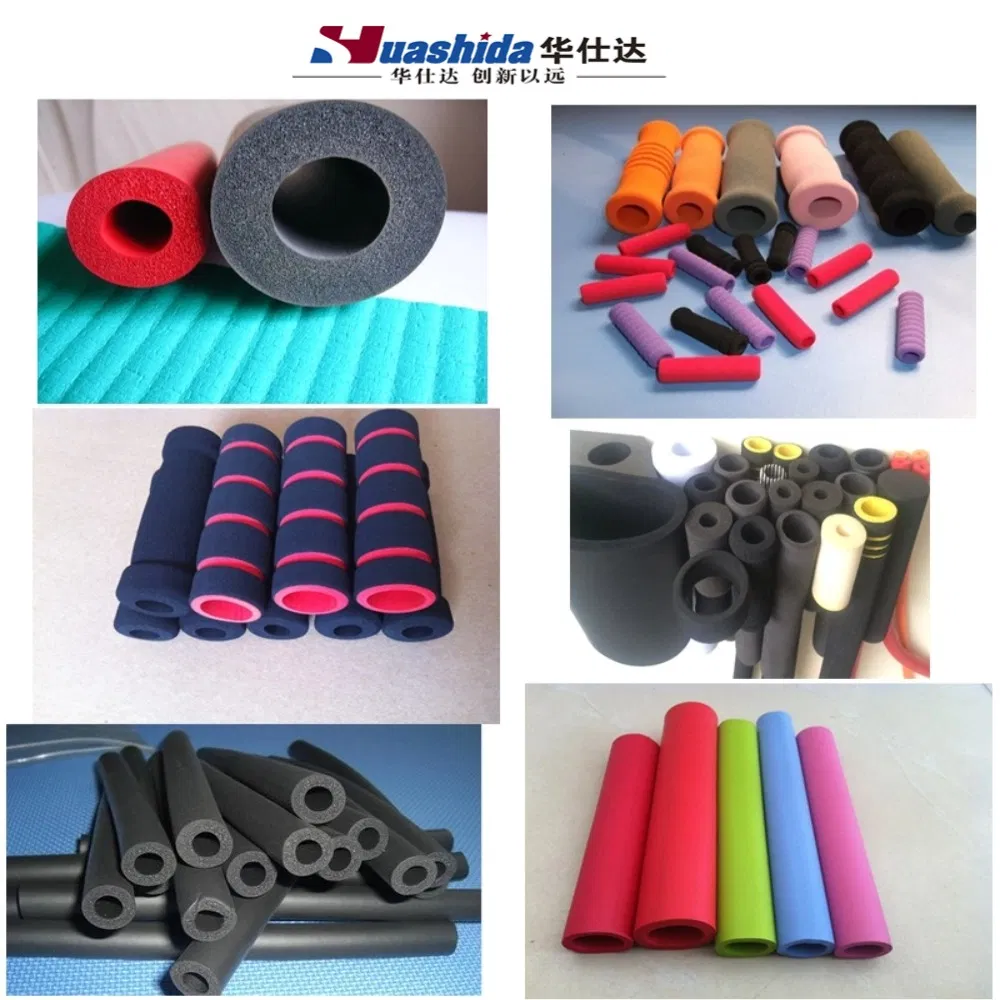

Tube Dia. : 6-50mm

Tube Thickness : 3-50mm

HS Code : 84119000

The rubber foam insulation pipe board production line adopts the latest international technology and fully automatic continuous production technology. It uses high-performance nitrile rubber (NBR), polyvinyl chloride (PVC) and EPDM rubber (EPDM) as the main raw materials, supplemented by a variety of high-quality additives, and is made of soft and efficient energy-saving materials for thermal insulation through a special foaming process.

Advanced Foam Insulation Pipe & Sheet Production Line

Designed for High-Efficiency Manufacturing of Eco-Friendly NBR/PVC Foam Materials

Key Features

1. High-Precision Extrusion

- Dual/triple-screw extruder system for uniform mixing of NBR/PVC and additives.

- Stable output of foamed profiles (pipes, sheets, panels) with consistent density.

2. Closed-Cell Foam Technology

- Advanced chemical/physical foaming process for ultra-low thermal conductivity (λ ≤ 0.034 W/m·K).

- Controlled cell structure for superior flexibility, waterproofing, and flame retardancy (meets GB8624 B1/UL94 standards).

3. CFC-Free & Eco-Compliant

- Fully halogen-free formulation (0% CFCs, HCFCs, HFCs) - complies with global environmental regulations (REACH, RoHS).

4. Multi-Format Production

- Quick-change molds for pipes (Φ6mm-Φ160mm) and sheets/panels (width ≤ 1000mm, thickness 5-50mm).

- In-line surface embossing/texturing options.

5. Automated Control System

- PLC/HMI integrated control for real-time monitoring of temperature, speed, and thickness.

- Energy-saving design reduces power consumption by 15-20% vs. conventional lines.

Technical Specifications (NRB-1000 Model)

Material Advantages (Final Product)

Foam insulation produced on the NRB-1000 line delivers:

Superior Insulation: Ultra-low λ value for energy-saving HVAC/R applications.

Flexible & Durable: -40°C to 105°C operating range, resistant to cracking.

Fire Safety: Self-extinguishing, low smoke density (ASTM E84 Class A).

Vibration & Acoustic Control**: Ideal for industrial piping and building systems.

Typical Applications

- HVAC duct insulation

- Refrigeration pipes (cold storage, chillers)

- Building insulation panels

- Automotive & marine thermal/acoustic barriers

- Industrial pipe jacketing

Why Choose Huashida?

- 22 Years of extrusion expertise

- Turnkey Solutions: From raw material advice to after-sales maintenance

- Customizable Lines: Tailored to output volume, product mix, and automation needs

Equipment List

About Packaging:

Wrap film packaging, if buyer need wooden pallets or wooden boxes, the cost is borne by the buyer.

12 months mechanical part, 6 months electrical part after delivery

Service:

Seller provide the technical service with free, and training the workers of buyers.

Installation and testing:

The seller should send enough technicians to the buyer's company for installation and testing the lines. The round trip ticket, accommodation, transportation, medicine treatment and insurance caused by the seller's expert in buyer's country and 150 US dollars per person per day will be covered by the buyer.

| Model number description | HSD-65 | HSD-90 | HSD-120 | HSD-150 | |

| Screw diameter | mm | 65 | 90 | 120 | 150 |

| Maximum screw speed | r/min | 70 | 19-58 | 4-40 | 4.6-48 |

| Feed roller diameter | mm | 65 | 72 | 120 | 145 |

| Motor power | kW | 22 | 55 | 90 | 132 |

| Heating method | |||||

| Maximum heating power | kW | 10 | 10 | 10 | 10 |

| Production capacity | kg/h | 85 | 165 | 335 | 500 |

The production line is superior to similar equipment at home and abroad in terms of extrusion speed, automation and safety performance, and its technical design, structural performance, and vulcanization technology have reached the international leading level.The rubber-plastic sponge insulation material produced is a closed-cell elastic structure, which has excellent characteristics such as softness, bending resistance, heat and cold resistance, flame retardant, waterproof, low thermal conductivity, seismic resistance and sound absorption.

|

|

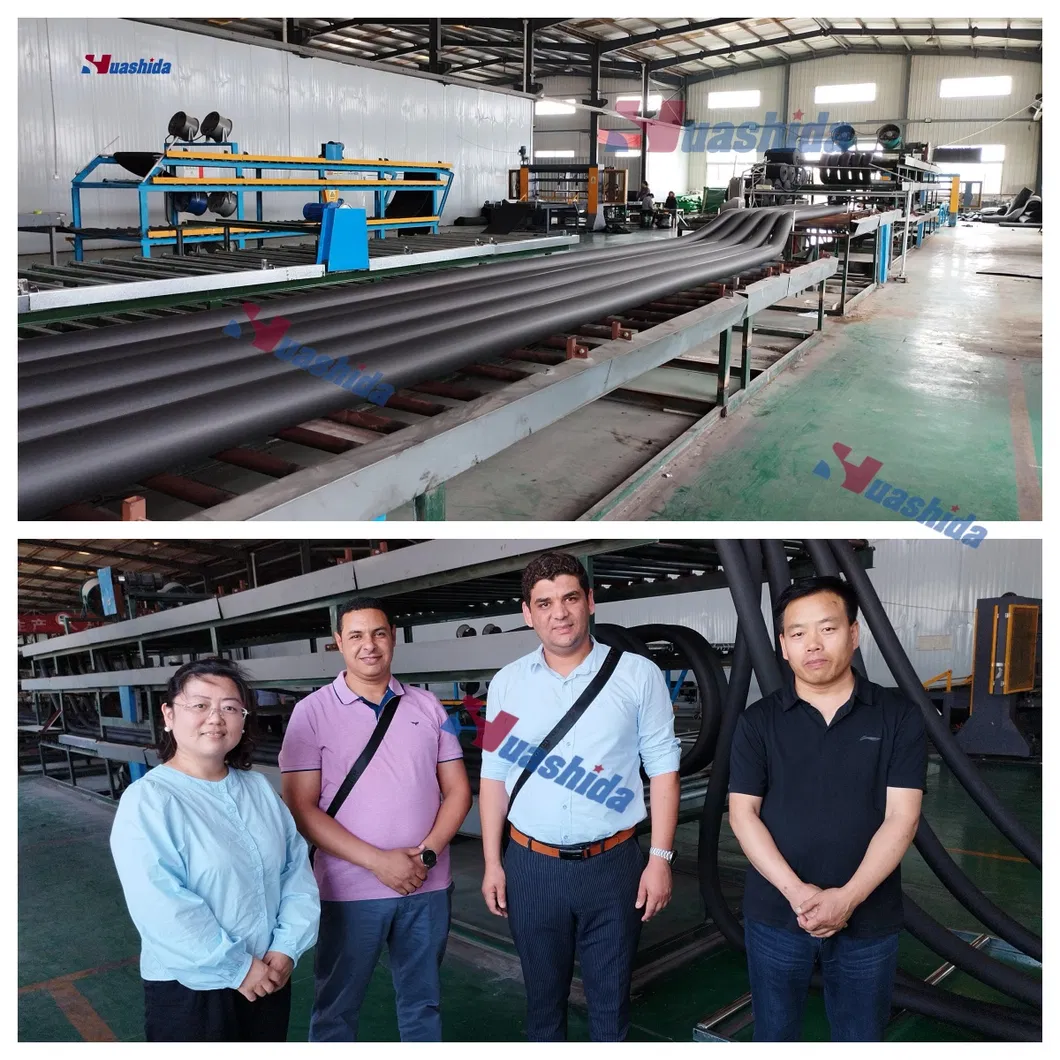

Air Conditioning Insulation Pipe NBR PVC Rubber Foam Insulation Material Production Line Equipment Images |